Tori Miller, Ph.D., assistant professor in the Department of Materials Science & Engineering, received an award from the Defense Advanced Research Projects Agency (DARPA) to develop advanced laser sheet metal forming technology to enable metal fabrication in space. With a goal of deploying robotic assembly technology on spacecraft for onboard part manufacturing capabilities, the five-year, $1.08 million study will help bypass the size constraints and costs of manufacturing large space systems on Earth.

Currently, virtually everything that goes into space, such as telescopes and solar arrays, must be built prior to launch, with size, weight and durability all factoring into (and limiting) design and production. With laser forming capabilities on board, the astronauts of tomorrow can manufacture and deploy the needed parts and equipment that will benefit multiple types of space missions, including astronomy, Earth observation, space exploration, telecommunications and national security.

Usable space on an orbiting vessel is at a premium, so any onboard manufacturing system must be designed with both size and task flexibility in mind. One proposed solution could be additive manufacturing or 3D printing, but it is unsuitable for printing the thin-walled parts that make up most spacecraft structures.

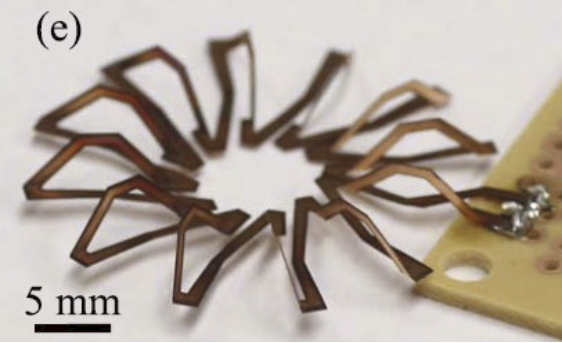

Laser sheet metal forming, a technique that uses laser-induced thermal distortion to help shape parts from sheet metal without the need for tools or other external forces, is an alternative manufacturing strategy. It’s also more adaptable to the types of structures that need to be built on-site while in space.

“Laser sheet metal forming is an ideal manufacturing technology for an orbiting spacecraft,” Dr. Miller said. “It’s fast, flexible, and can cut, form and potentially weld a wide range of materials, including metals, ceramics and semiconductors. Unfortunately, one major issue with laser forming is the same problem with additive manufacturing: while complex geometries can routinely be achieved with extreme precision, the material’s final properties can’t be accurately predicted. As a result of that uncertainty, laser-formed components typically cannot be put into engineering service – particularly onboard a spacecraft.”

However, Dr. Miller’s approach to implementing laser forming technology differs from previous attempts. In the past, laser forming was approached primarily from a controls or systems engineering standpoint. In her research, Dr. Miller addresses it as a metallurgical engineer focusing on the material’s evolution during its thermomechanical processing.

“Nearly all previous research treated material parameters such as yield strength and grain size as isotropic constants which would not change during the laser forming process – even as the material is subjected to tens or hundreds of local laser passes,” Dr. Miller said. “In some experiments, the material parameters were treated as unchanging even as the bend region was partially melted.”

Dr. Miller proposes an innovative modeling strategy: incorporating the time- and temperature-dependent evolution of material parameters based on local state variables into more conventional finite element method and machine learning modeling approaches.

“These material-process models will enable laser-forming technology to have an unprecedented level of simultaneous control over geometry and mechanical properties,” Dr. Miller said. “For example, the model would help us predict the impact that heat from a repair would have on surrounding structural components.”

Some of the earliest proposed manufacturing concepts for spacecraft were also sheet metal fabrication. The Grumman Beam Builder was developed in the 1970s and could cut, bent and ultrasonically weld rolled sheets of aluminum alloy into triangular trusses. While reasonably effective, this concept was limited to a single geometry and a short list of usable materials. Due to these substantial constraints, research efforts in that era were ultimately redirected to on-orbit assembly processes rather than manufacturing.

In the decades since, though, technology has allowed that initial concept to advance far enough to warrant another look finally.

“It’s a significant step forward in this field,” Dr. Miller said. “It’s been exciting to think about the next steps of testing in a thermal vacuum chamber at NASA and eventually on the International Space Station.”

Royce Copeland

MSE|NE Marketing and Communications